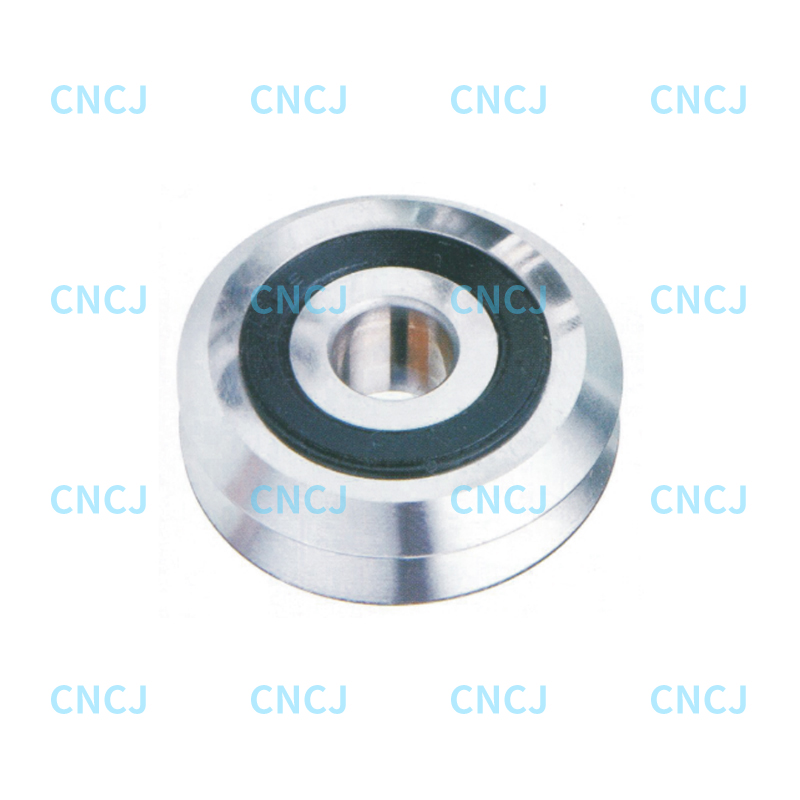

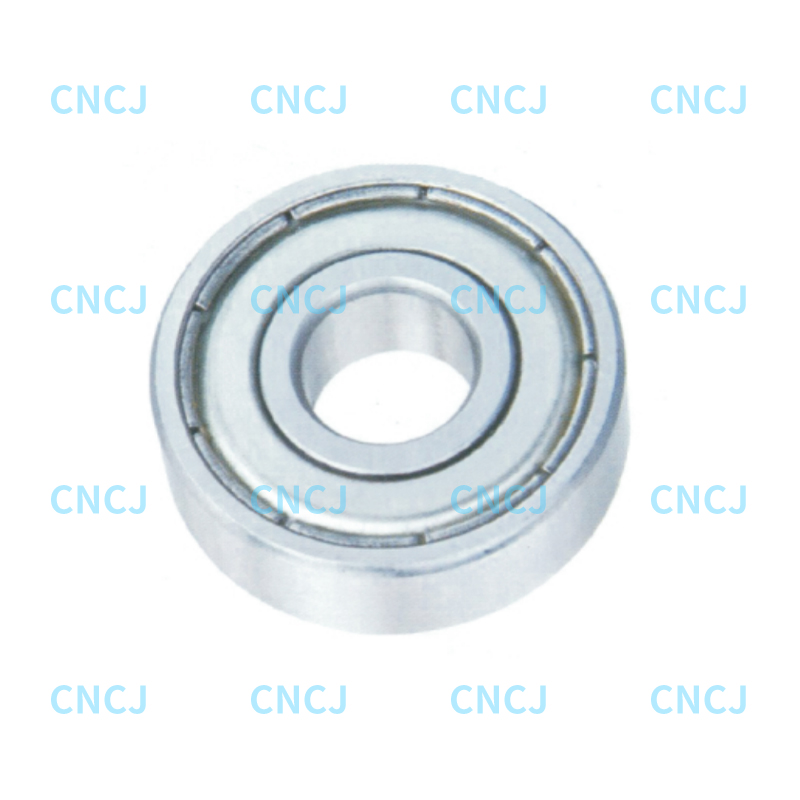

The V-shaped groove design of Vee'D bearings is inspired by the in-depth exploration of high-efficiency transmission mechanisms. Compared with traditional bearings, the unique feature of V-shaped grooves is that they can achieve more precise guidance and support, thereby significantly reducing frictional resistance during operation. The core of this design is that the V-shaped groove ensures that rolling elements (such as balls or rollers) maintain contact during movement, effectively avoiding sliding friction and unnecessary energy loss that may exist in traditional designs.

In order to achieve the low friction effect of V-shaped grooves, Vee'D bearings use a high-precision manufacturing process. From material selection to processing process, every link is strictly controlled to ensure that every detail of the bearing can reach the state. For example, the rolling elements of the bearing are made of high-purity, high-strength alloy materials, which have been precision ground and heat-treated to make their surfaces as smooth as mirrors, further reducing the friction coefficient. At the same time, the V-shaped groove itself has also been specially processed to ensure that its shape accuracy and surface roughness meet the design requirements, thereby minimizing friction while achieving the guiding function.

The V-shaped groove design of Vee'D bearings has shown amazing results in practical applications. In high-speed running equipment, this design can significantly reduce friction heat and wear and extend the service life of the bearing. At the same time, due to the reduction of frictional resistance, the power consumption of the equipment is also reduced, thereby achieving the purpose of energy saving and emission reduction. In addition, the V-shaped groove design also enables the bearings to have better stability and reliability when withstanding heavy loads and impacts, ensuring long-term stable operation of the equipment.

The V-groove design of Vee'D bearings has been widely used in multiple industries. In the field of semiconductor manufacturing, its high precision and low friction characteristics provide a strong guarantee for precision machining; in medical equipment, low friction operation reduces equipment noise and vibration, providing a more comfortable treatment environment for patients; in the aerospace field, High reliability and long life have become indispensable key elements. In addition, Vee'D bearings are widely used in warehousing logistics, food processing, papermaking equipment and other fields, providing strong support for automation upgrades in various industries.

The V-shaped groove design of Vee'D bearings is not only a model of current technological innovation, but also an important direction for future development. With the continuous advancement of science and technology and the continuous demand of the market, Vee'D bearings will continue to conduct in-depth exploration and innovation in material science, manufacturing technology and intelligent control. By continuously optimizing design and improving performance, Vee'D bearings will bring users more efficient, reliable, and environmentally friendly transmission solutions, and promote global industrial manufacturing to a higher level.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español