Wanshun Bearing's 52 and 53 series double-row angular contact ball bearings inherit the essence of traditional double-row design and incorporate Wanshun's unique technological innovation. The double-row ball layout has been carefully calculated and optimized to ensure the balance and stability of the bearing when bearing complex loads. The precise control of the contact angle by Wanshun's engineering team enables these two series of bearings to exert the optimal axial load capacity under different working conditions, meeting a wide range of needs from light load to heavy load, from low speed to high speed. Not only that, Wanshun Bearing also fully considers the strict requirements for sealing and lubrication under different working conditions. Some models use advanced RS-type contact sealing structure, which effectively isolates the intrusion of harmful substances such as dust and moisture in the external environment, ensuring the cleanliness and lubrication of the bearing. At the same time, Wanshun's self-developed lubrication system ensures low friction and low wear of the bearing during high-speed operation, extends the service life of the bearing, and reduces the user's maintenance cost.

1. Product Overview

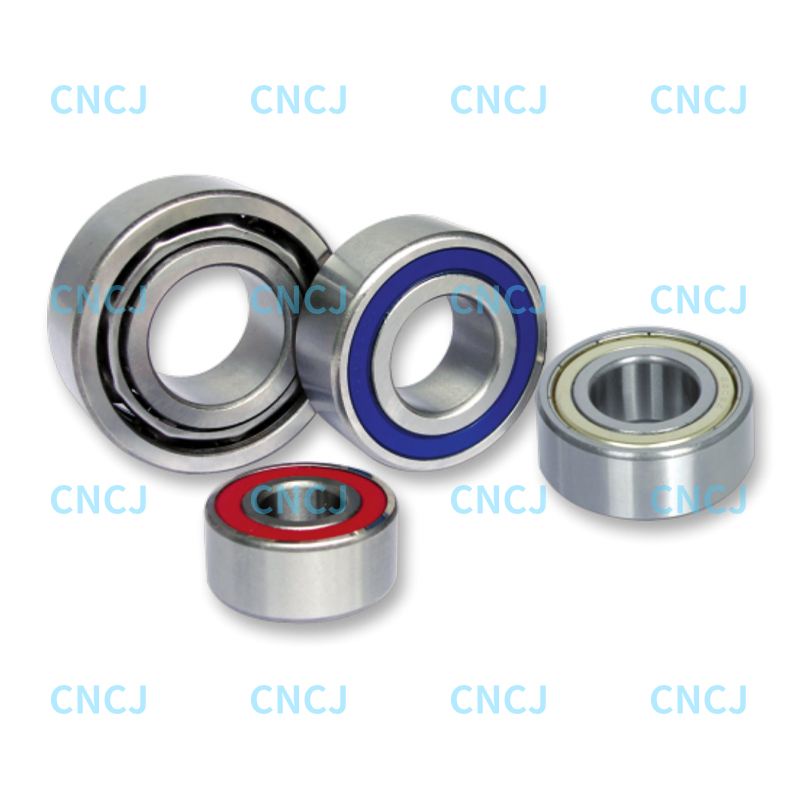

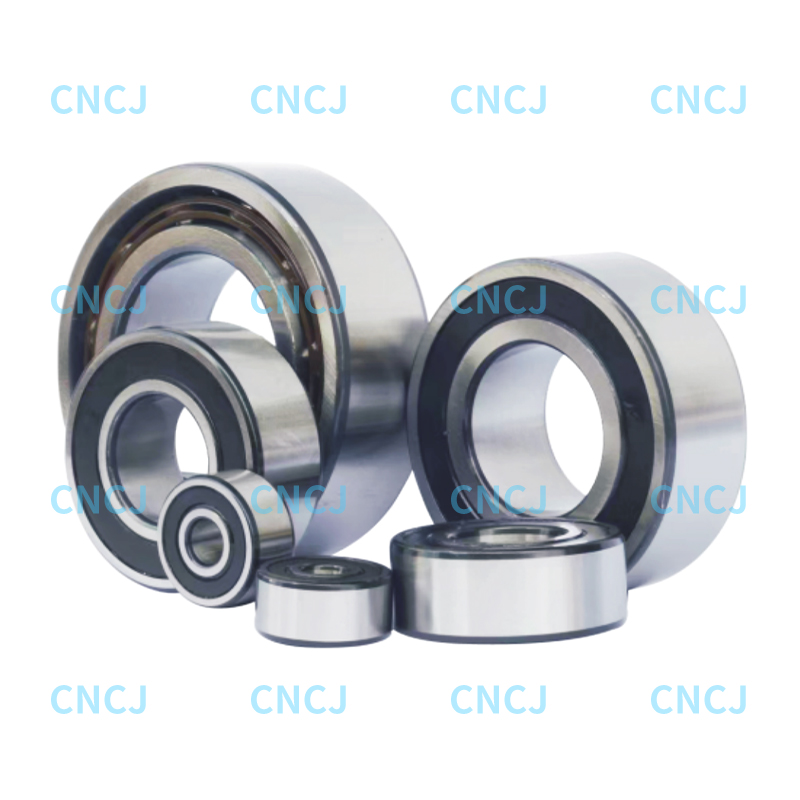

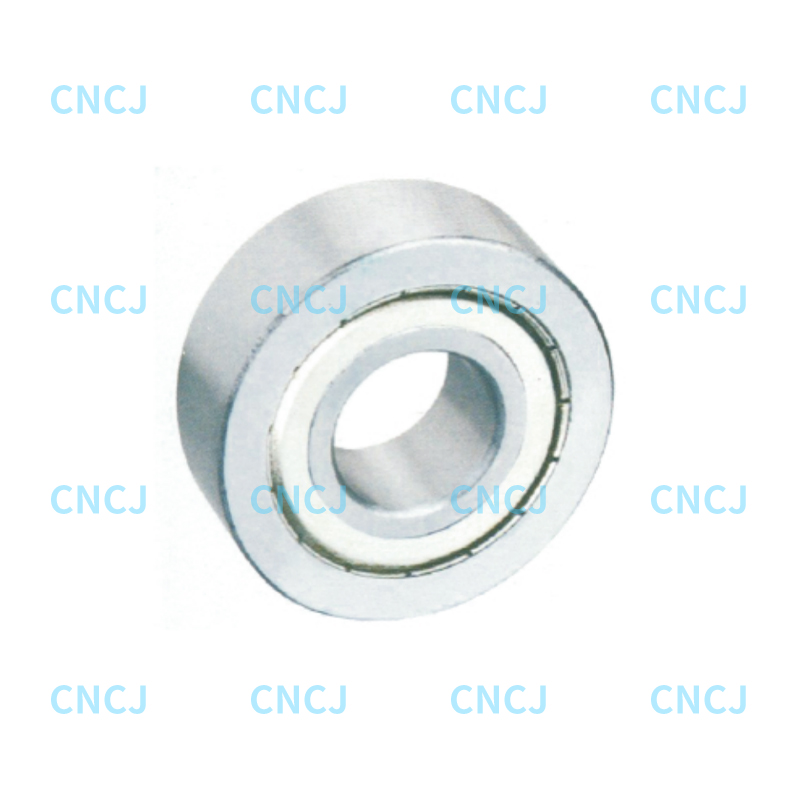

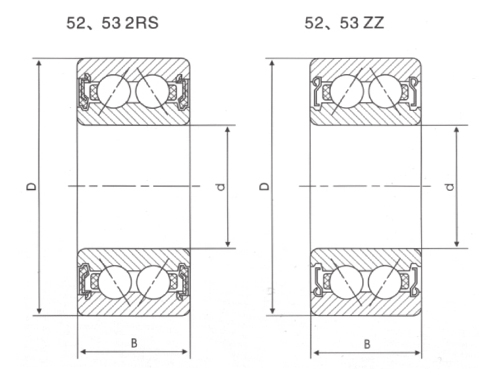

As an important member of the angular contact ball bearing family, the design inspiration of the 52 and 53 series double-row angular contact ball bearings comes from a deep understanding of the needs for efficient and high-precision transmission. Both series of bearings adopt a double-row structure, and through the point contact between two sets of balls and the inner and outer rings, they can simultaneously bear radial and axial loads. Compared with single-row angular contact ball bearings, the double-row design not only improves the bearing's load-bearing capacity, but also optimizes space utilization, making the structure more compact.

2. Structural Features

Double-row design: Both the 52 and 53 series bearings adopt a double-row ball layout. This design enables the bearing to more effectively disperse and resist axial loads while bearing radial loads, thereby improving the overall rigidity and stability of the bearing.

Contact angle optimization: The contact angle of angular contact ball bearings is an important factor in determining their axial load-bearing capacity. The 52 and 53 series bearings usually have contact angles ranging from 15° to 40°. This design enables the bearings to maintain excellent axial load-bearing capacity under different working conditions. In addition, as the contact angle increases, the axial load capacity of the bearing also increases, which is suitable for occasions that need to bear large axial loads.

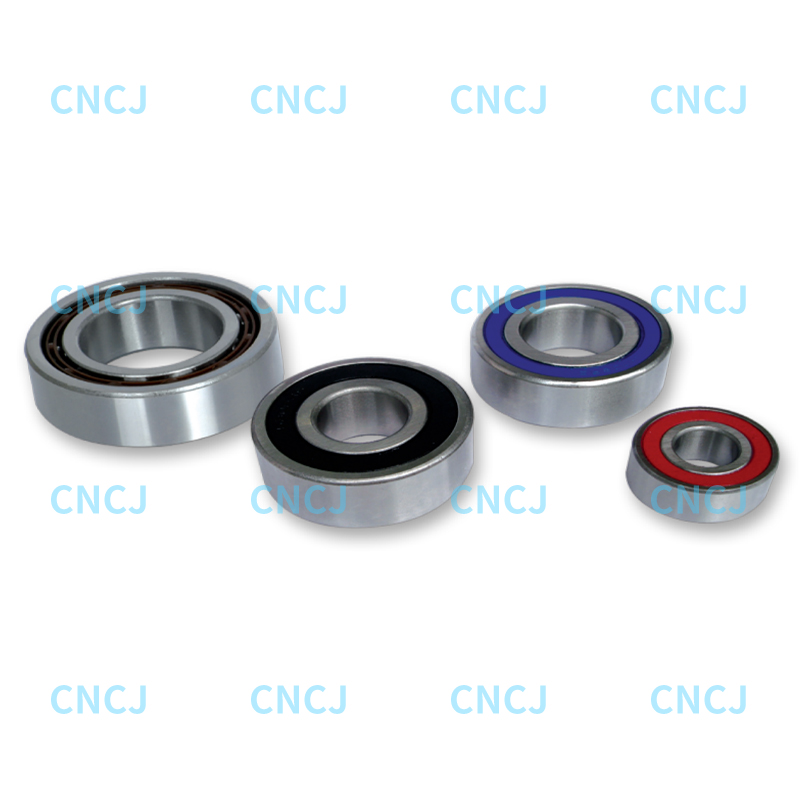

Sealing and lubrication: In order to meet the use requirements under different working conditions, 52 and 53 series bearings provide a variety of sealing and lubrication solutions. For example, some models use a contact seal structure (such as RS type) to effectively prevent dust, moisture and other impurities from invading the interior of the bearing; at the same time, through reasonable lubrication design, low friction, low wear and long life of the bearing under high-speed operation are ensured.

3. Performance advantages

High load capacity: The double-row design enables the 52 and 53 series bearings to have a high load capacity in both radial and axial directions, which is suitable for applications under harsh working conditions such as heavy loads and high speeds.

High speed stability: Thanks to the optimized ball layout and contact angle design, this series of bearings can still maintain good stability and precision under high-speed operation, ensuring the reliable operation of the transmission system.

Wide adaptability: 52 and 53 series bearings are widely used in machine tool spindles, wind power generation, automobile wheel hub bearings, pumps and other fields, meeting the needs of different industries for high-precision and high-reliability bearings.

4. Industry Application

Machine tool spindle: In the machine tool manufacturing industry, the performance of the spindle bearing directly affects the machining accuracy and stability of the machine tool. 52 and 53 series double-row angular contact ball bearings have become the ideal choice for machine tool spindles with their high precision, high rigidity and high stability.

Wind power generation: The speed increaser, spindle and other key parts of wind turbines have extremely high requirements for the bearing's load capacity and reliability. 52 and 53 series bearings have been widely used in the field of wind power generation due to their excellent performance characteristics.

Automobile wheel hub bearings: With the rapid development of the automobile industry, the requirements for wheel hub bearings are getting higher and higher. 52 and 53 series bearings have become one of the important choices for automobile wheel hub bearings with their high speed stability, low noise and long life.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español