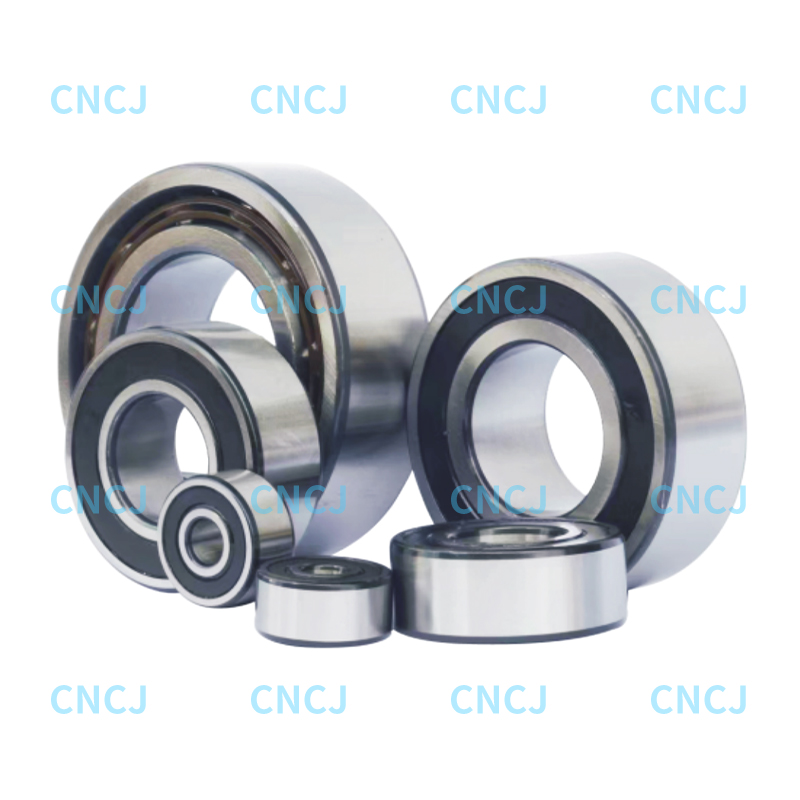

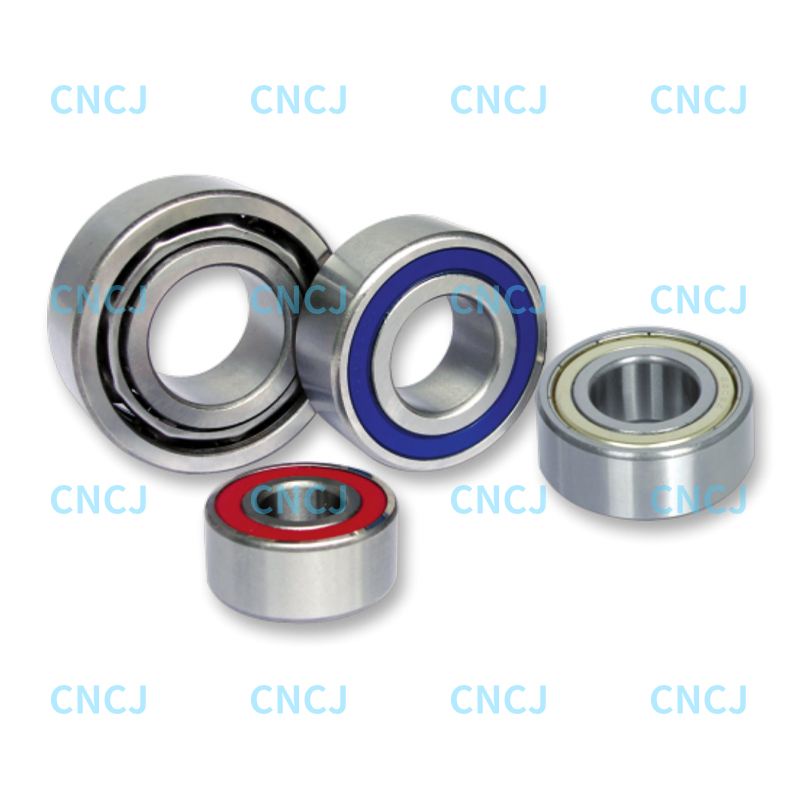

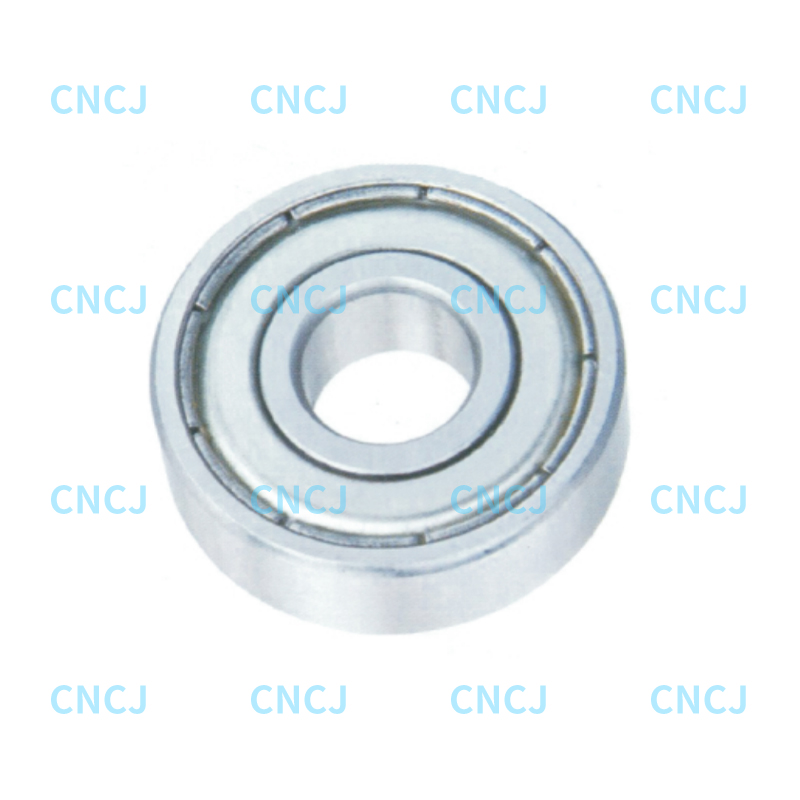

32, 33 Series Double Row Angular Contact Ball Bearings can meet the requirements of high-speed and heavy-load operation. 32, 33 Series Double Row Angular Contact Ball Bearings adopt advanced processing technology, including precision grinding, heat treatment and other processes, to ensure that the geometric accuracy and surface quality of each bearing component meet high standards. This high-precision processing helps to reduce the friction and heat generated by the bearing when it rotates at high speed, thereby increasing the speed limit of the bearing.

Inside the bearing, the carefully designed lubrication channels and oil storage spaces constitute an efficient lubrication system. These channels not only ensure that the lubricant can be delivered to each key friction point quickly and accurately, but also achieve uniform distribution of the lubricant through a complex flow channel layout. This design greatly reduces the local overheating and wear problems caused by uneven lubrication, effectively reduces the friction coefficient, and thus improves the efficiency and stability of the bearing when it rotates at high speed. At the same time, the lubricant can effectively absorb and take away the heat generated by friction during the flow process, reduce the bearing temperature, prevent thermal damage, and further extend the service life of the bearing.

The production process of 32, 33 Series Double Row Angular Contact Ball Bearings strictly follows high-precision processing and assembly standards. From the selection and processing of raw materials to the final assembly, every link is strictly quality controlled. High-precision processing ensures the dimensional accuracy and shape accuracy of each bearing component, and reduces the vibration and noise problems caused by excessive or too small assembly clearance. The sophisticated assembly technology further improves the overall performance of the bearing, enabling it to maintain extremely low noise and vibration levels during operation. This design not only improves the overall performance of the equipment, but also creates a more comfortable working environment for users, while also helping to reduce damage to other components caused by vibration, thereby extending the service life of the entire equipment.

The double-row layout design enables the bearing to distribute the load more flexibly when subjected to complex load conditions, effectively dispersing axial and radial loads, thereby significantly improving the bearing's load capacity. Each row of raceways bears part of the load. This sharing mechanism not only improves the overall strength of the bearing, but also enables the bearing to maintain a stable operating state under heavy load conditions. In addition, the double-row layout also helps to balance the stress distribution inside the bearing, reduce fatigue damage caused by stress concentration, and further improve the reliability and service life of the bearing.

In order to ensure the stable performance of the bearing under heavy load conditions, the key components of the 32, 33 Series Double Row Angular Contact Ball Bearings, such as the inner and outer rings, steel balls and cages, are made of high-quality materials. These materials have been carefully selected and rigorously tested, and have high strength, high hardness, high wear resistance and good corrosion resistance. They can maintain stable physical and chemical properties in extreme working environments and resist performance degradation caused by factors such as heavy loads, high temperatures, and corrosion. This material selection not only improves the bearing's load capacity and service life, but also provides users with a more reliable and durable product choice.

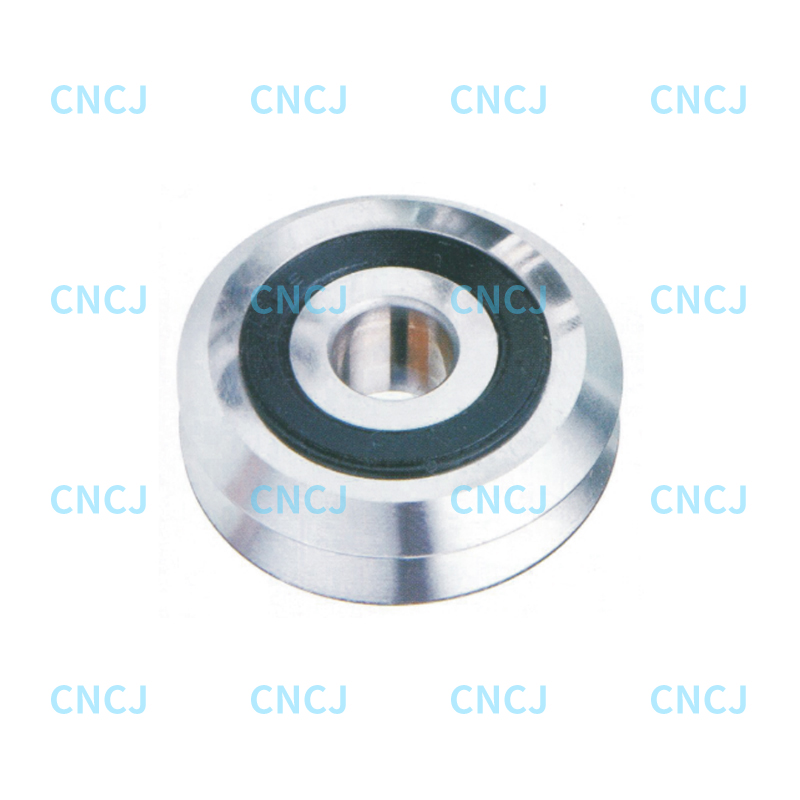

In order to further improve the bearing's load capacity and anti-deformation ability, some models of the 32, 33 Series Double Row Angular Contact Ball Bearings also adopt a reinforced structural design. These designs include increasing the ball loading gap, using a thicker cage, and optimizing the raceway shape. Increasing the ball loading gap can increase the bearing's capacity and stiffness, making the bearing more stable when under heavy loads; while the thicker cage can provide better support and protection to prevent bearing failure due to deformation or damage. These innovative designs not only enhance the mechanical properties of the bearings, but also improve their adaptability and reliability under complex working conditions.

32, 33 Series Double Row Angular Contact Ball Bearings can fully meet the high-speed and heavy-load operation requirements with their advanced processing technology, optimized lubrication structure, low noise and vibration characteristics, and strong heavy-load bearing capacity. These advantages make this series of bearings widely used in machine tool spindles, gearboxes, wind power generation, motors, automotive wheel hub bearing units, and industrial automation equipment.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español