On a busy industrial production line, the stable operation of each mechanical equipment is a guarantee of production efficiency. As the "heart" of these machines, the health of double-row ball bearings is a concern for every maintenance personnel. So, in daily maintenance and inspection, what key indicators and phenomena should we pay attention to?

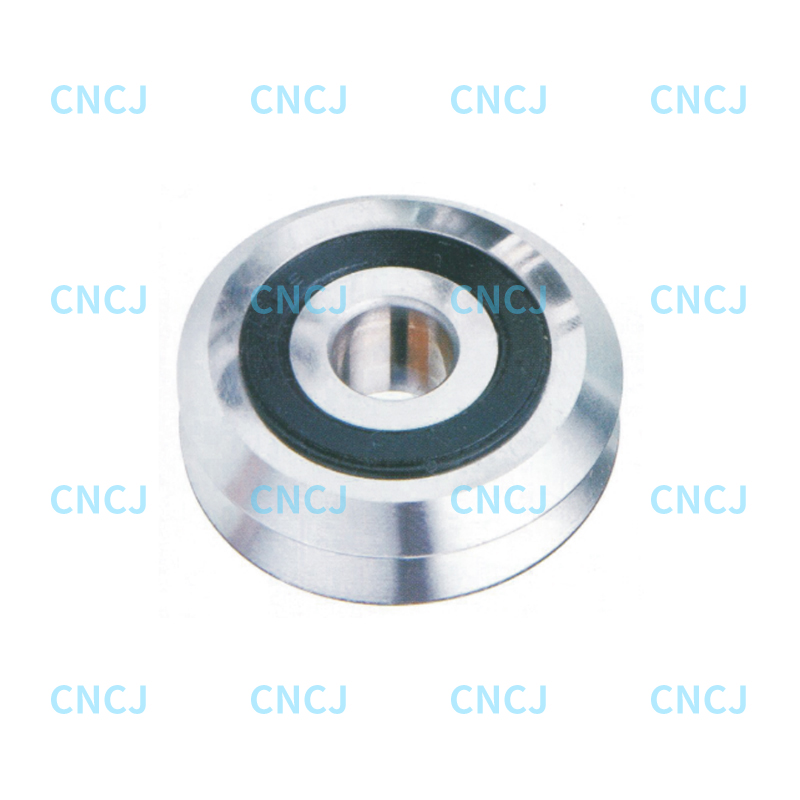

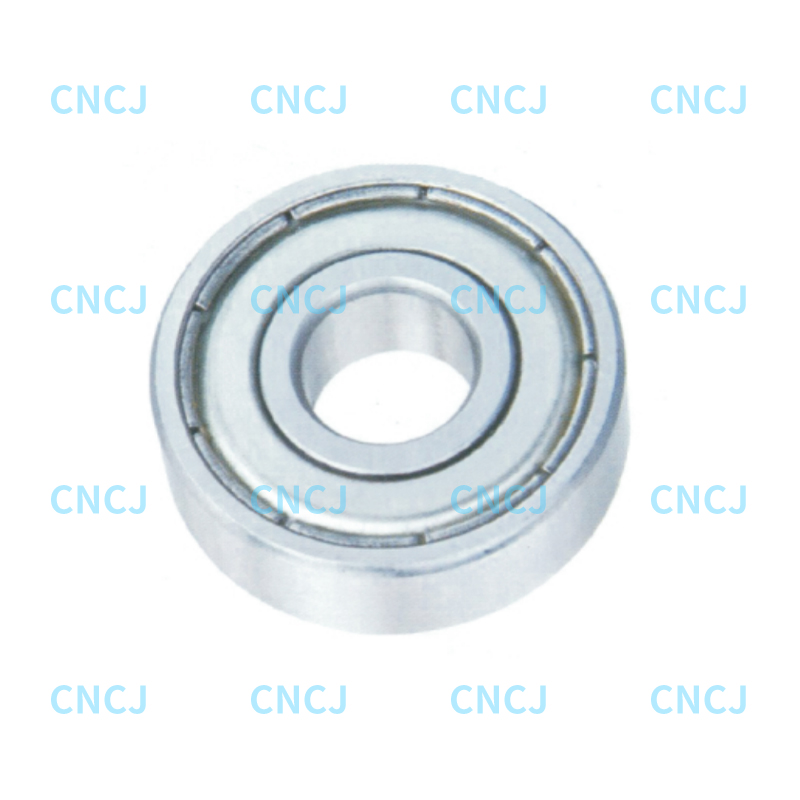

Appearance inspection is the first step to discover potential problems with double-row ball bearings. Users should regularly check whether the surface of the bearing is flat and smooth, and whether there are scratches, rust or oil accumulation. These seemingly minor flaws are often a precursor to bearing wear or poor lubrication. At the same time, it is also necessary to confirm that the markings on the bearing are clear and readable to ensure that the selected bearing meets the use requirements of the equipment. Through careful appearance inspection, we can promptly discover and deal with potential problems to avoid the expansion of faults.

During the operation of mechanical equipment, double-row ball bearings will emit specific sounds and vibrations. Users should learn to listen to these "languages" to judge the operating status of the bearing. Normal bearing operation should be smooth and silent. If abnormal noise or increased vibration occurs, it may be caused by wear, looseness or poor lubrication inside the bearing. At this time, the machine should be stopped for inspection immediately to avoid further development of the fault.

Temperature is one of the important indicators reflecting the operating status of double-row ball bearings. Under normal operating conditions, the temperature of the bearing should be kept within a certain range. If the temperature rises abnormally, it may be caused by excessive load on the bearing, poor lubrication or failure of the cooling system. Users should regularly use tools such as infrared thermometers to detect the bearing temperature. Once an abnormality is found, the cause should be immediately identified and measures should be taken to solve it.

Reasonable lubrication is the key to extending the life of double-row ball bearings. Users should regularly check the lubrication of the bearings to ensure that the lubricating oil or grease is sufficient and clean. During the inspection, attention should be paid to changes in the color, odor and viscosity of the lubricating oil, as well as whether there are impurities mixed in. At the same time, according to the use of the equipment and the manufacturer's recommendations, the lubricating oil or grease should be replaced regularly to maintain the good lubrication of the bearing.

In order to ensure the long-term and stable operation of double-row ball bearings, users should establish a regular inspection and record system. After each inspection, detailed records of the bearing's appearance, operating conditions, temperature, lubrication conditions, etc. are required. These records not only help to find and solve problems in a timely manner, but also provide important references for subsequent maintenance. In addition, by comparing and analyzing the inspection records of previous times, the bearing's life and performance change trends can be predicted, providing a scientific basis for preventive maintenance of equipment.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español