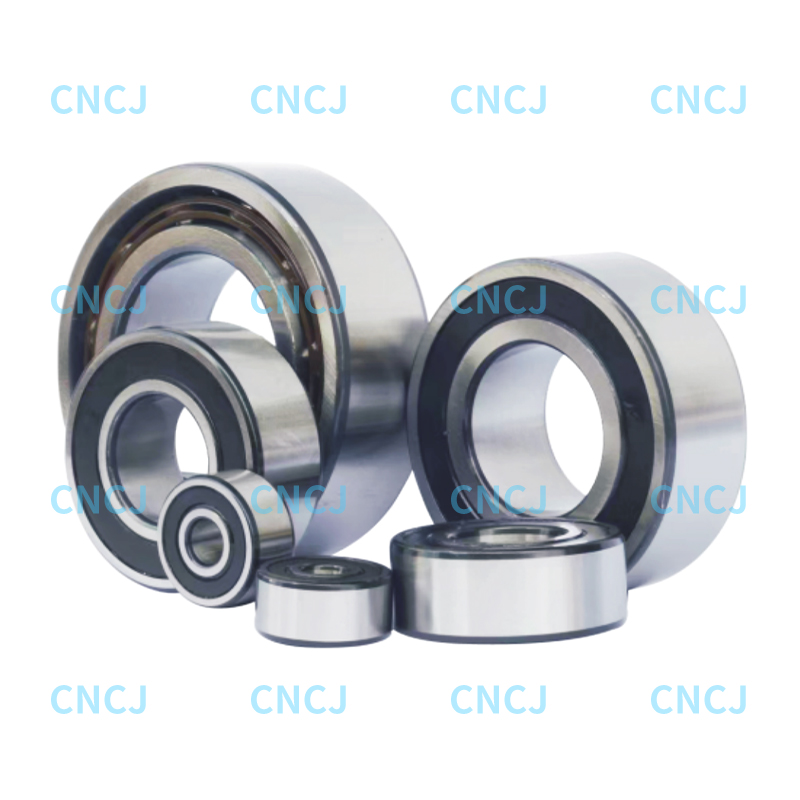

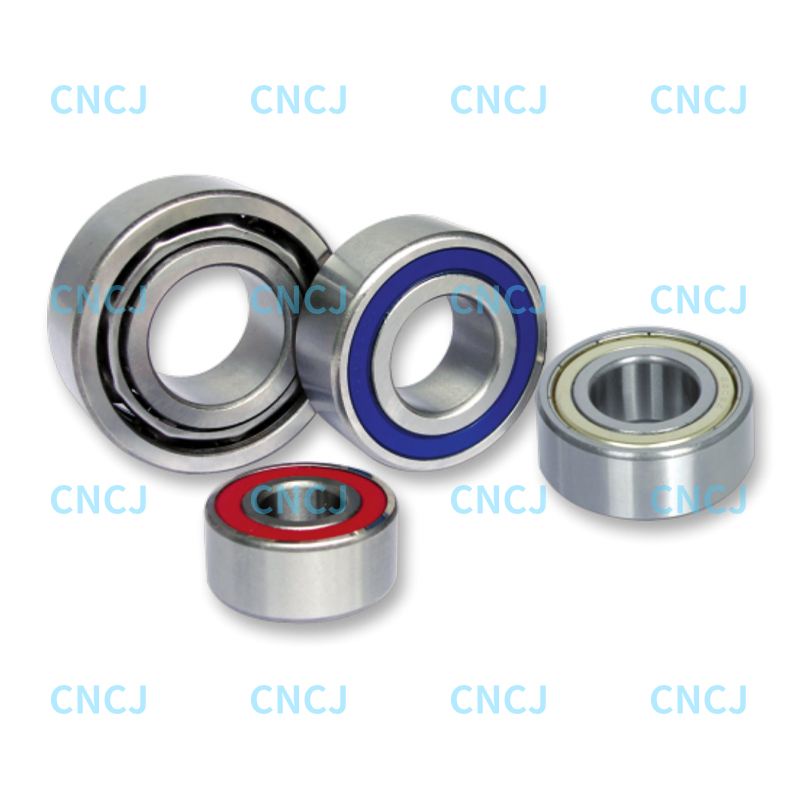

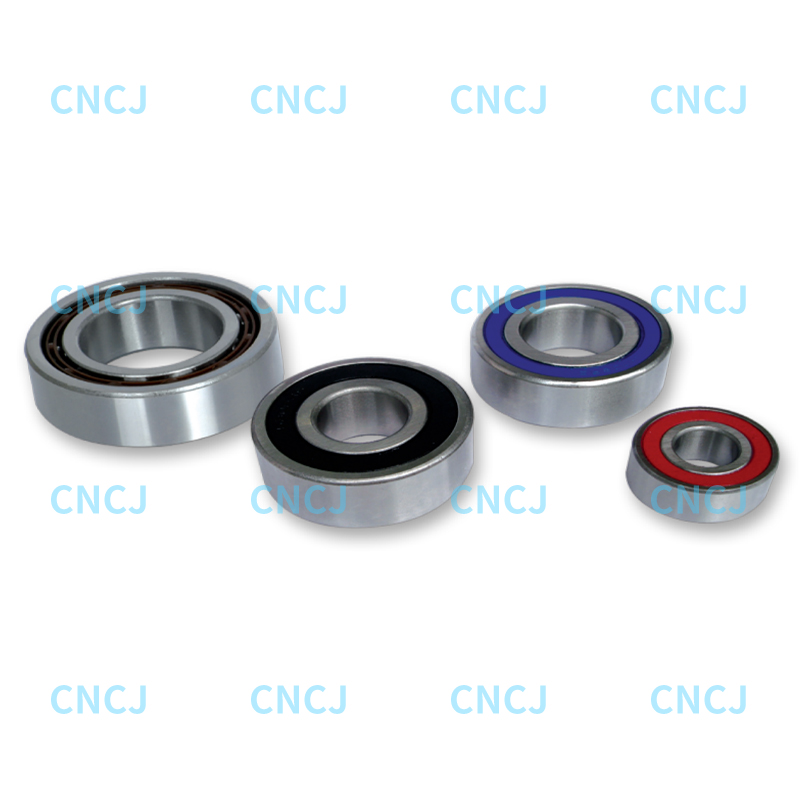

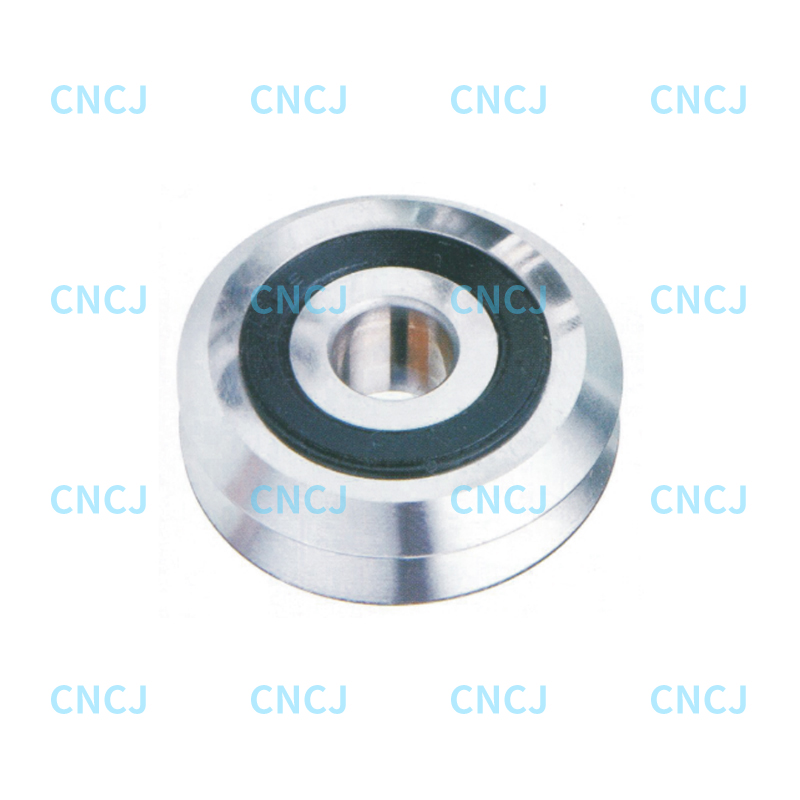

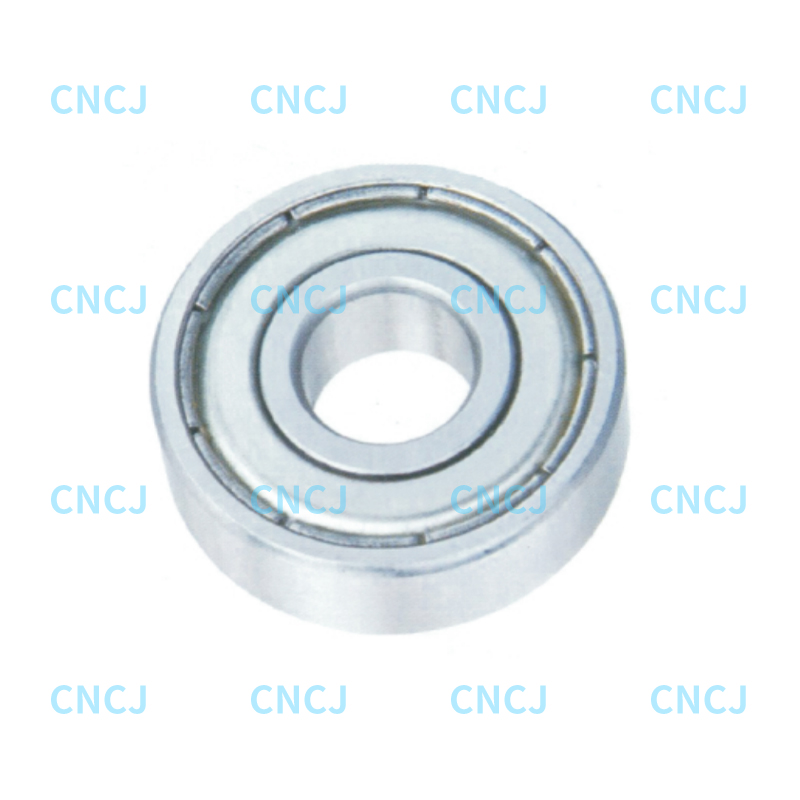

In the industrial production process, the operating efficiency and reliability of the equipment are directly related to the stability and productivity of the entire production system. As a key component in mechanical equipment, the performance of the bearing has an important impact on the operating quality of the equipment. High-precision, low-noise double-row angular contact ball bearings are widely used in various industrial fields, meeting the strict requirements of the equipment for accuracy, load capacity, speed and stability.

1. Improve the operating accuracy of equipment

Many applications in industrial equipment require high operating accuracy, such as machine tools, precision instruments, robots, etc. In these scenarios, any slight deviation may lead to production errors or product quality degradation. High-precision double-row angular contact ball bearings can ensure that the equipment maintains a precise axis position when rotating at high speed, thereby avoiding vibration and displacement errors caused by insufficient bearing accuracy. This high-precision feature is essential for the smooth operation and precise processing of industrial equipment.

2. Bear multi-directional loads and improve load-bearing capacity

Due to its special design structure, double-row angular contact ball bearings can simultaneously bear radial and axial bidirectional loads. The two rows of rolling elements in this bearing can evenly distribute the load, increase the bearing's load-bearing capacity, and are suitable for industrial equipment that needs to withstand large axial loads. For example, in applications such as wind power generation and automotive transmission systems, the equipment will generate radial and axial forces during operation. Double-row angular contact ball bearings can effectively disperse these forces to ensure long-term stable operation of the equipment.

3. Reduce noise and improve the working environment

Low-noise bearing design is essential for the working environment in industrial production, especially in applications with strict requirements for noise control, such as medical equipment, semiconductor manufacturing, and precision machinery. Double-row angular contact ball bearings can reduce the friction noise generated by bearings when rotating at high speeds by optimizing the geometric design of the rolling elements and using high-quality lubricants. This not only helps improve the working environment, but also improves operator comfort while reducing noise interference with sensitive equipment or process flows.

4. Improve the operating speed and efficiency of equipment

High-precision, low-noise double-row angular contact ball bearings can maintain stable operation at higher speeds due to their small friction coefficient. Their high-precision design ensures that no excessive vibration or heat is generated when rotating at high speeds, thereby extending the service life of the equipment and improving production efficiency. For example, in high-speed motors, turbomachinery and other equipment, the speed and stability of the bearings determine the maximum operating capacity of the equipment. The design of double-row angular contact ball bearings meets the requirements of high-speed operation, helping industrial equipment to maintain smooth operation while improving production efficiency.

5. Extend the service life of equipment and reduce maintenance costs

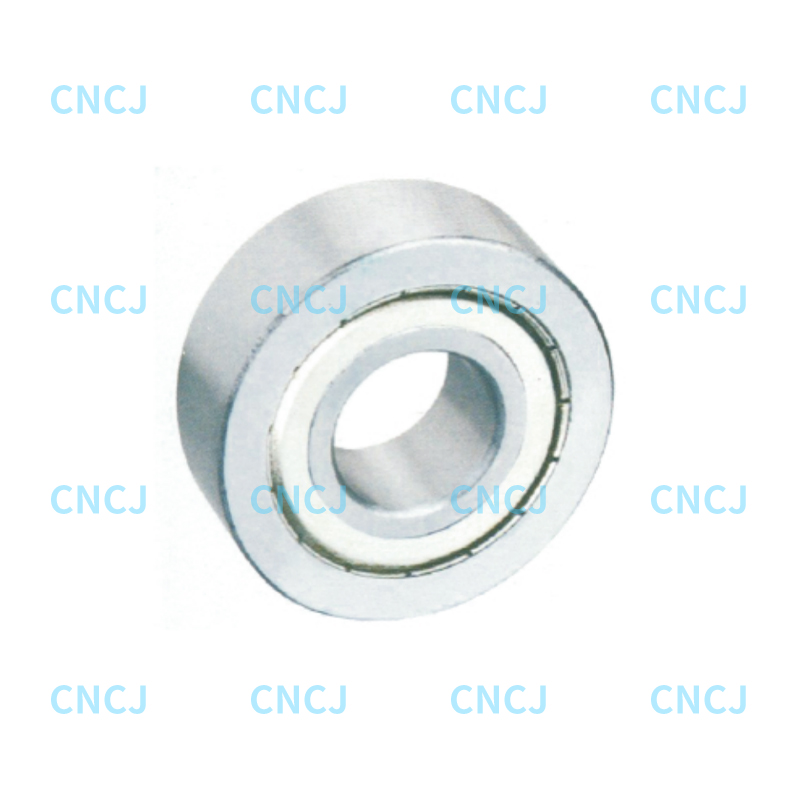

Double-row angular contact ball bearings have excellent wear resistance and fatigue resistance, and can maintain long-term stable operation in harsh working environments. Its high-precision manufacturing and good lubrication effect minimize the friction and wear of the bearings, reduce the frequency of bearing replacement, and thus extend the overall service life of the equipment. For industrial production, this not only reduces the maintenance cost of the equipment, but also avoids production interruptions caused by frequent shutdowns for maintenance.

6. Adapt to complex working environments

In some industrial applications, equipment may need to work under complex conditions such as high temperature, high humidity, corrosive or high load. High-precision, low-noise double-row angular contact ball bearings are usually made of high-temperature resistant and corrosion-resistant materials, and can maintain stable operating performance and adapt to various harsh working environments. Its stable performance can ensure that the equipment can maintain efficient production capacity under different working conditions and reduce the risk of equipment failure caused by environmental changes.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español