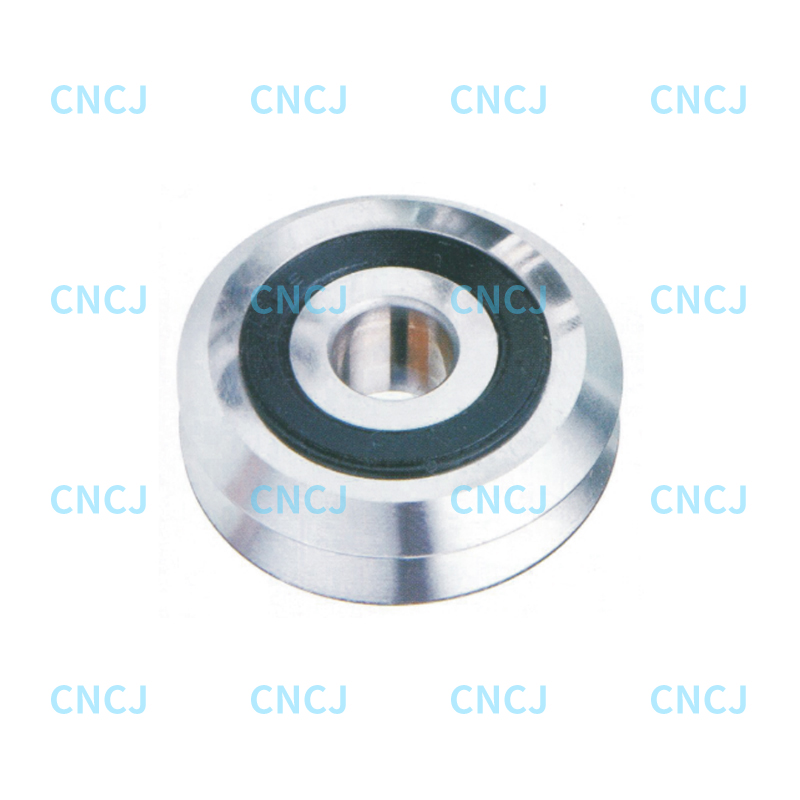

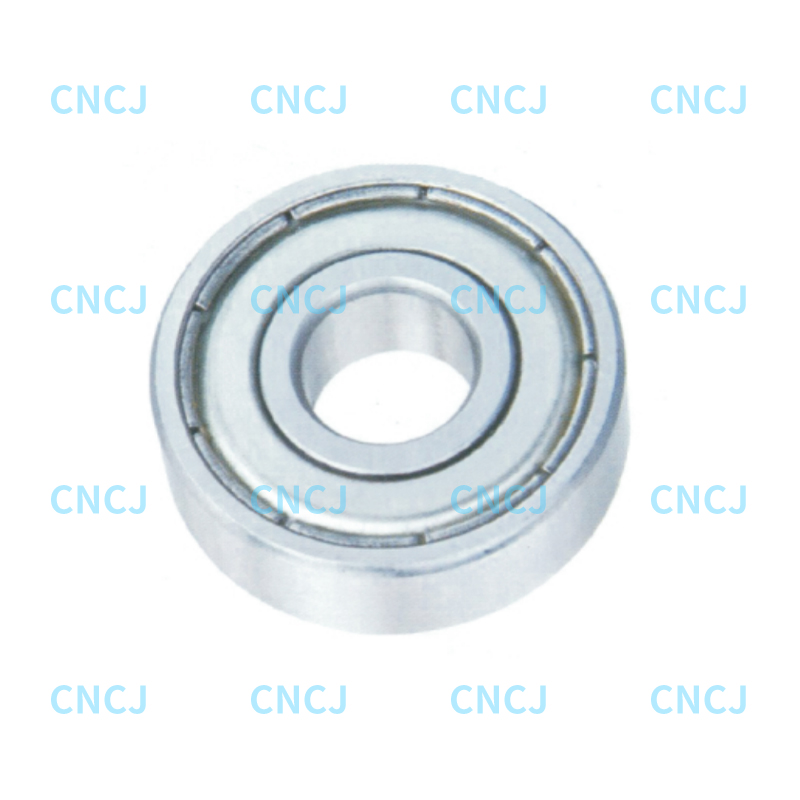

W series linear track roller bearings are precision designed, versatile mechanical components that are widely used in industrial systems that require smooth linear motion. Its unique W-groove design, excellent load capacity, and excellent durability make it an ideal choice for a variety of application scenarios in modern industry. This article will analyze in detail the main industrial application scenarios of W series linear track roller bearings and their specific role in these fields.

1. Automated production line

In automated factories, conveying and positioning are key links. W series roller bearings are widely used in conveyor systems and guide devices of robotic arms due to their smooth rolling performance. This bearing can maintain low noise and high precision at high speeds, making the movement of automated equipment smoother and effectively improving the efficiency and reliability of production lines.

2. Packaging equipment

Packaging machinery often requires fast and precise positioning and movement, such as the slide rail system in sealing machines, labeling machines, and sorting machines. The high load capacity and compact design of the W series roller bearings enable them to withstand the inertial impact of equipment when it is running fast, while maintaining high positioning accuracy, meeting the requirements of the modern packaging industry for efficiency and stability.

3. Logistics and conveying systems

In the fields of logistics and warehousing, equipment such as conveyor lines and stackers require strong load capacity and long-term durability. The W series roller bearings are suitable for logistics track pulley systems. Their smooth rolling characteristics reduce running resistance, can effectively reduce energy consumption and extend the service life of equipment, and are an indispensable and important component in logistics and conveying systems.

4. Industrial robots

Industrial robots need to perform complex movements in three-dimensional space. As an important part of the guide rail system, the W series roller bearings provide smooth and precise linear motion support. Whether it is a welding robot or a spraying robot, the bearings can ensure trajectory stability and repeatability, thereby improving the reliability and efficiency of robot operation.

5. CNC machine tools and machining centers

In CNC machine tools and machining centers, the accuracy of linear motion components directly determines the processing quality. Due to their low friction and high rigidity, the W series roller bearings can maintain precise linear motion under high load conditions. It is often used in machine tool slides and tool slide systems to help achieve high-precision processing of complex workpieces.

6. Medical equipment

In the medical industry, many devices require precise and quiet linear motion, such as CT scanners, X-ray machines, and laboratory automation equipment. The low-noise design and dust-free operation characteristics of the W series roller bearings are very suitable for these scenes with high cleanliness and high precision requirements, providing reliable support for medical diagnosis and experimental operations.

7. Stage machinery and film and television equipment

Stage lifts and film and television track equipment require smooth and quiet linear sliding to achieve precise props and camera movements. The W series roller bearings perform well in this application, and their smooth operating characteristics provide seamless support for live shooting and stage performances, ensuring the perfect presentation of the audience experience.

8. Building curtain wall and sliding door systems

Glass curtain walls and large sliding door systems commonly seen in modern buildings need to bear large weights while achieving smooth opening and closing operations. Due to their high load capacity and corrosion-resistant design, the W series roller bearings are suitable for these scenes that are exposed to the external environment for a long time, providing a durable and reliable solution for buildings.

9. Agricultural machinery

Linear motion components in agricultural machinery, such as guide systems in seeders, fertilizer spreaders, and harvesters, can also make good use of W series roller bearings. This bearing can not only operate in harsh outdoor environments, but also has dust resistance and impact resistance, adapting to the high-intensity operation requirements of agricultural machinery.

10. Aviation and transportation equipment

In aviation maintenance systems and rail transportation equipment, linear guides require high precision, durability, and seismic resistance. W series roller bearings meet these requirements and are suitable for key components such as aircraft maintenance slides and EMU door control systems, providing reliable technical support for these high-demand industries.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español