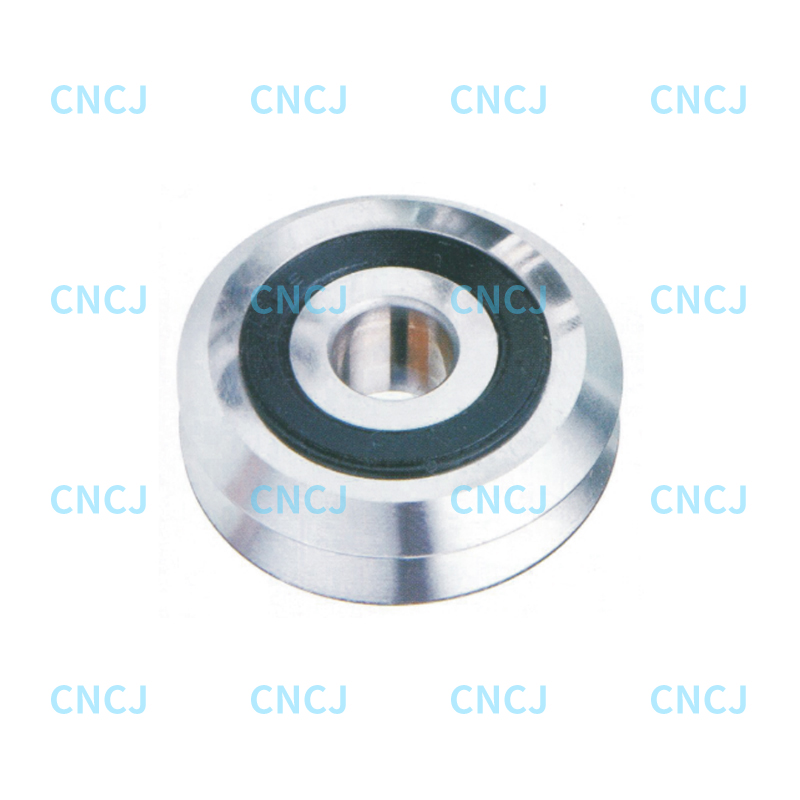

Track roller ball bearings are critical components in various heavy-duty machinery and equipment, providing essential support in applications that require high load-carrying capabilities. These bearings are designed to handle both radial and axial loads while offering smooth, efficient motion even under challenging conditions. In high-load applications, such as industrial machinery, conveyor systems, and heavy construction equipment, the performance and reliability of track roller ball bearings are key to maintaining productivity and minimizing downtime.

1. High Load-Carrying Capacity

One of the most significant advantages of track roller ball bearings is their ability to support high radial and axial loads. Unlike traditional ball bearings, track rollers are specifically designed to bear greater loads due to their larger contact surface area and robust construction. The inclusion of multiple rows of rolling elements in some track roller designs allows them to distribute the load more evenly, reducing stress on individual components and improving the bearing's overall load-carrying capacity.

This feature makes track roller ball bearings ideal for heavy-duty machinery in industries such as mining, construction, and manufacturing, where components are subjected to significant forces. In these environments, the ability to withstand high loads without failure is crucial to ensuring continuous operation and preventing equipment breakdowns.

2. Durability and Long Lifespan

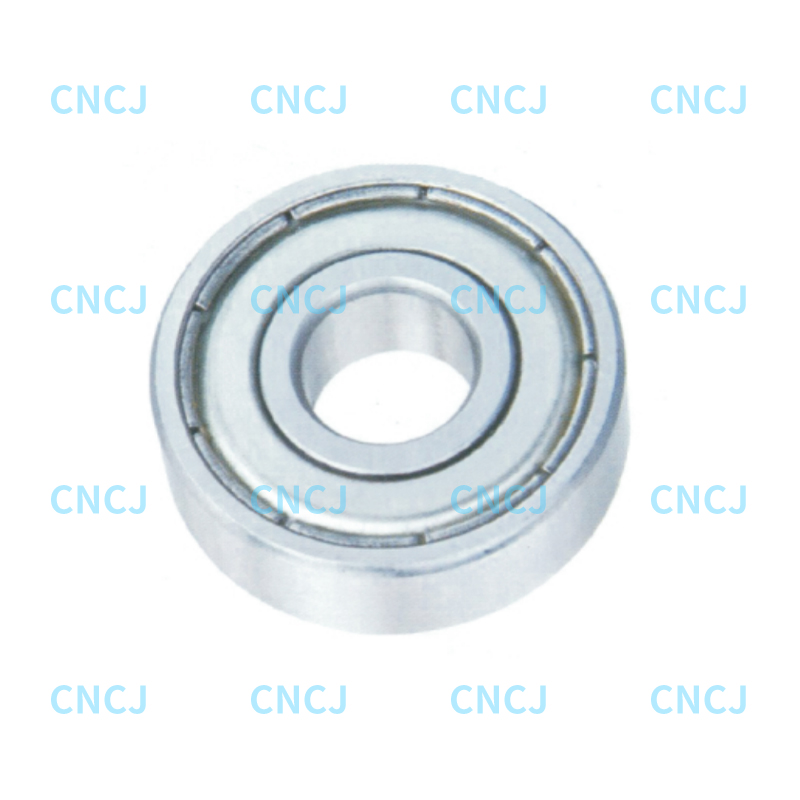

Track roller ball bearings are built to last, even in high-load conditions. Their design, featuring robust steel races and multiple rows of steel balls or rollers, ensures that they can handle repeated heavy loads without significant wear. The use of high-quality materials like carbon steel, stainless steel, or ceramic in their construction enhances their durability and resistance to wear and tear.

In high-load applications, where machinery operates under constant stress, the durability of track roller ball bearings is critical. Bearings that wear down too quickly can lead to costly maintenance, replacements, and unplanned downtime. By choosing track roller ball bearings, businesses can extend the service life of their machinery and reduce the frequency of bearing replacements, ultimately lowering operational costs.

3. Smooth and Reliable Operation

Despite the heavy loads they support, track roller ball bearings are designed to provide smooth and reliable motion. The rolling elements, typically steel balls or rollers, reduce friction between moving parts, allowing for efficient power transmission and minimizing energy losses. This smooth operation is particularly important in systems such as conveyor belts or robotic arms, where continuous and precise movement is required.

In high-load applications, reducing friction is essential not only for energy efficiency but also for maintaining the overall performance of the machinery. Track roller ball bearings help achieve this by ensuring that the system operates with minimal vibration and noise, contributing to a more stable and predictable work environment.

4. Resistance to Harsh Environments

Many high-load applications take place in challenging environments where exposure to dirt, moisture, extreme temperatures, and heavy impacts is common. Track roller ball bearings are designed to function reliably even in such conditions. Many high-quality track roller bearings are equipped with seals or shields to protect the internal components from contaminants, preventing premature wear and failure.

Additionally, track roller ball bearings made from materials like stainless steel are highly resistant to corrosion, making them suitable for use in outdoor, marine, or chemical-processing environments where rust and corrosion are concerns. The ability to perform under harsh conditions reduces the need for frequent maintenance and increases the overall reliability of equipment.

5. Reduced Maintenance Requirements

In high-load applications, the cost of equipment downtime and maintenance can be substantial. Track roller ball bearings reduce the need for frequent servicing by providing long-term, reliable performance under heavy loads. Their advanced design and ability to handle extreme forces mean they require less maintenance compared to other types of bearings, which often need to be replaced more frequently.

Additionally, some track roller ball bearings are designed to be self-aligning or feature built-in self-lubrication systems, which further reduce maintenance needs. By minimizing the frequency of bearing inspections, lubrication, and replacement, track roller ball bearings help lower operational costs and improve the efficiency of high-load systems.

6. Ability to Handle Axial and Radial Loads Simultaneously

Track roller ball bearings are uniquely suited to handle both axial (thrust) and radial loads simultaneously. This capability is especially important in applications where the load is applied from multiple directions, such as in conveyor systems or linear motion guides.

The design of track roller bearings allows them to support axial loads along with the radial loads without compromising performance. This dual-load capacity makes track roller bearings versatile and reliable in systems that require complex, multidirectional movement under heavy loads.

7. Enhanced Shock Load Resistance

High-load applications often subject bearings to shock loads—sudden, unexpected forces that can lead to catastrophic failures in inadequate bearings. Track roller ball bearings are designed to resist shock loads and sudden impact forces. Their robust structure and multiple rolling elements help distribute these forces more evenly across the bearing, reducing the likelihood of bearing failure under shock loading conditions.

This shock-load resistance is essential in industries like construction and mining, where equipment experiences frequent jolts, impacts, or vibrations from heavy machinery or moving loads. Track roller ball bearings contribute to maintaining system integrity and preventing downtime due to bearing damage from shock forces.

8. Cost-Effectiveness in the Long Run

While track roller ball bearings may come at a higher upfront cost than standard bearings, their superior load capacity, durability, and reduced maintenance needs make them a more cost-effective solution in the long run. With fewer replacements and less downtime required, businesses can benefit from the increased productivity and reduced operational costs that result from the use of track roller ball bearings.

By offering long-term reliability and minimizing repair costs, track roller ball bearings provide an excellent return on investment for high-load applications.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español