When selecting W-series linear rail roller bearings, determining the appropriate size and load capacity is a key step to ensure efficient operation and extended service life of the equipment. This process involves multiple aspects, including application requirements, load calculations, and environmental factors.

Understanding the application requirements is the first step in selecting the right bearing. Different mechanical systems and working environments will have different requirements for the size and load capacity of the bearing. For example, in high-speed applications, bearings need to have higher precision and stability, while under heavy load conditions, bearings need to withstand greater loads. Therefore, clarifying the application scenario of the required bearing is the basis of the selection process.

Load calculation is the core of determining bearing performance. Bearings are subjected to different types of loads during operation, including radial loads and axial loads. Before selecting a bearing, it is necessary to calculate the specific load requirements of the bearing for each component in the system. Typically, manufacturers will provide relevant load data and calculation formulas to help users estimate the required load capacity. In addition, it is also important to consider operating conditions, such as changes in dynamic loads and static loads.

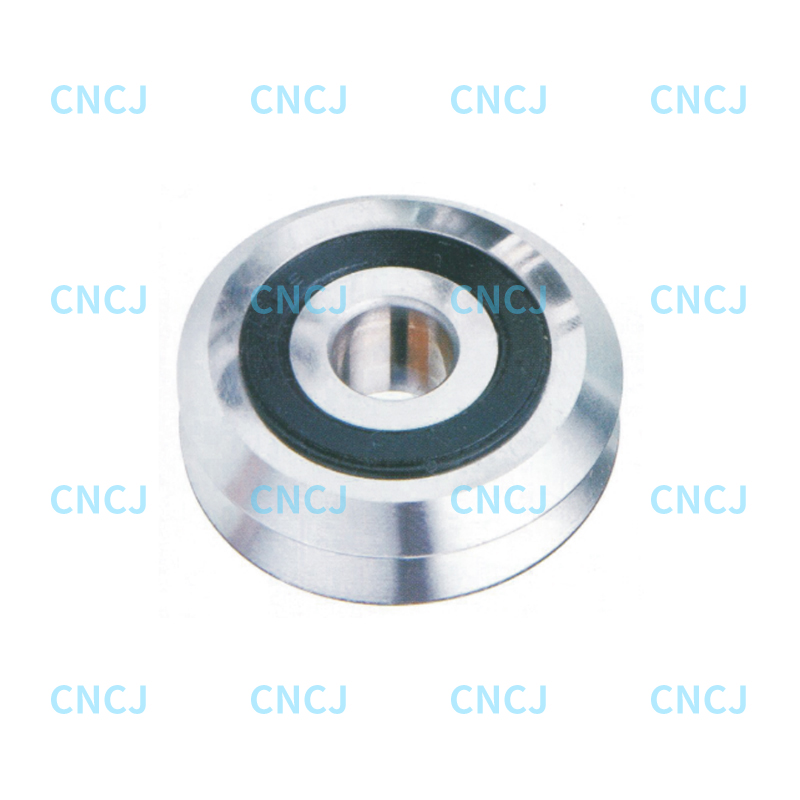

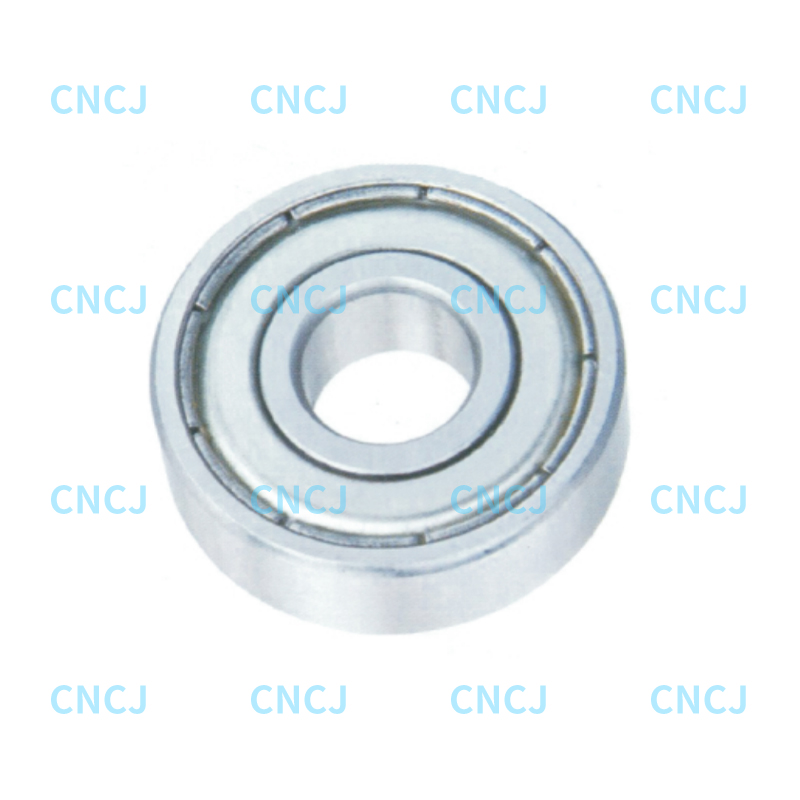

Size selection is also a key factor. The dimensions of the bearing, such as the outer diameter, inner diameter and thickness, directly affect its load-bearing capacity and adaptability. When selecting, it is necessary to ensure that the size of the selected bearing matches the mechanical structure to avoid operating problems caused by inappropriate size. Usually, W series bearings are available in a variety of specifications, and users can choose according to actual needs.

Environmental factors should not be ignored. The working environment of the bearing has a significant impact on its performance and life. External conditions such as temperature, humidity, and pollutants can affect the working state of the bearing. For example, in a hot or humid environment, special materials or lubricants may need to be selected to ensure the reliability of the bearing. In addition, considering factors such as vibration and impact, it is also necessary to select a suitable bearing type to enhance its durability.

It is recommended that users consult professional engineers or technicians when selecting W series linear rail roller bearings to obtain more accurate advice and solutions. By comprehensively considering application requirements, load calculations, size matching and environmental factors, the optimal performance and reliability of the selected bearing under specific working conditions can be ensured, thereby achieving efficient operation of the equipment.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español