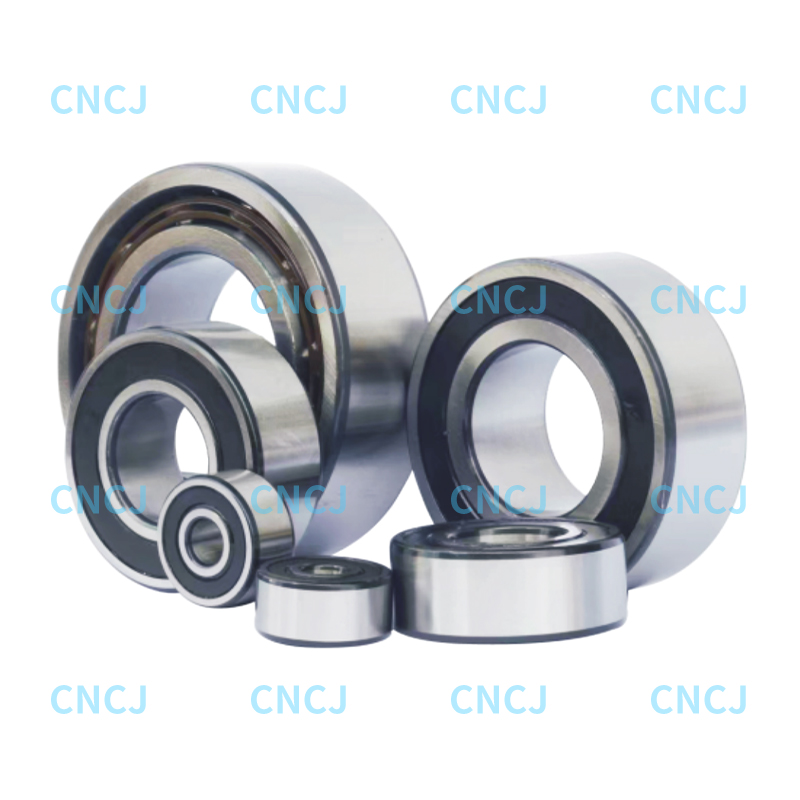

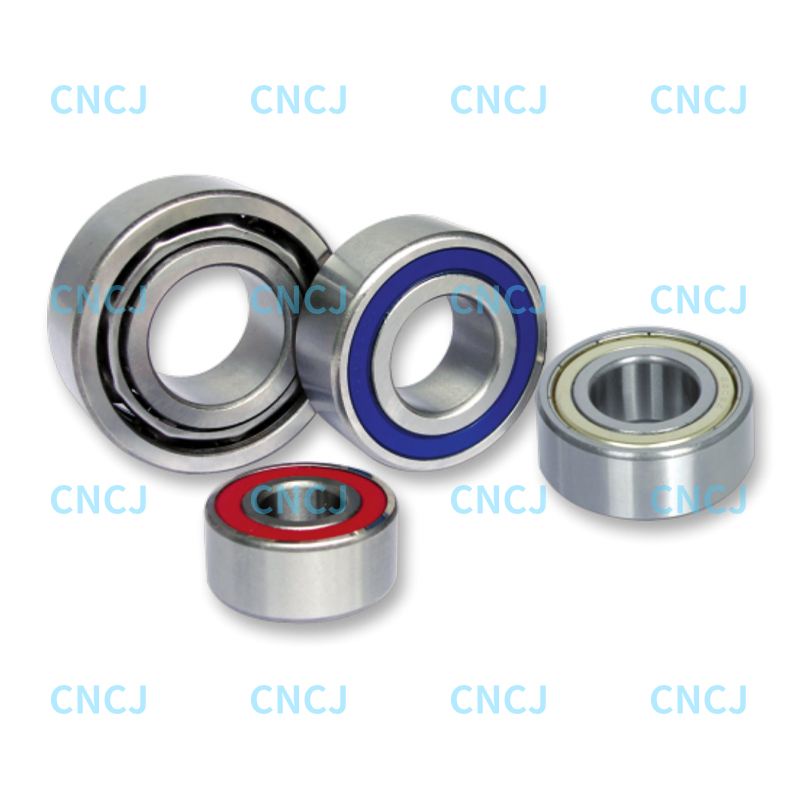

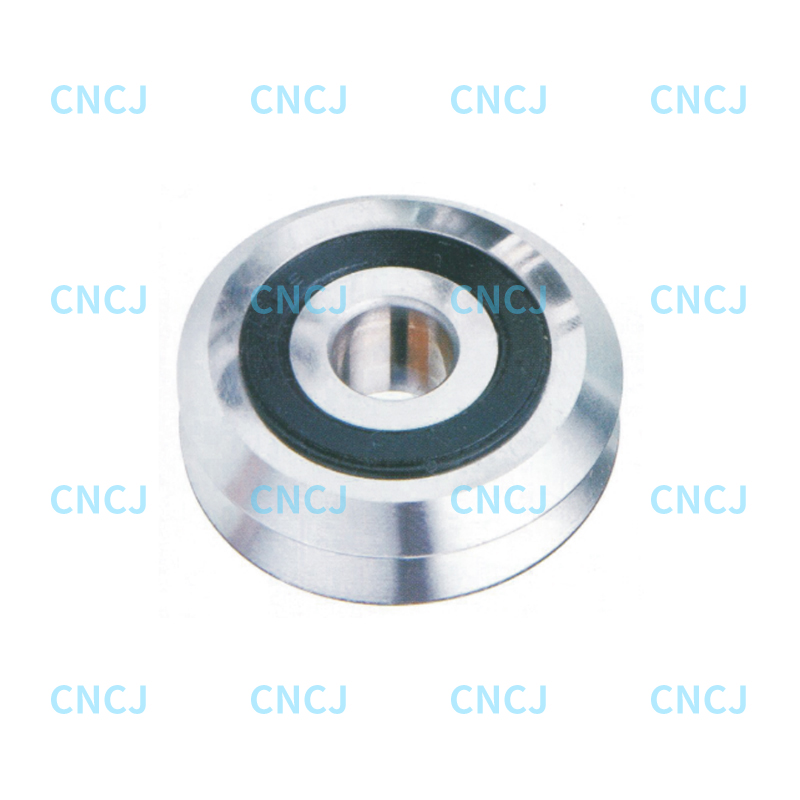

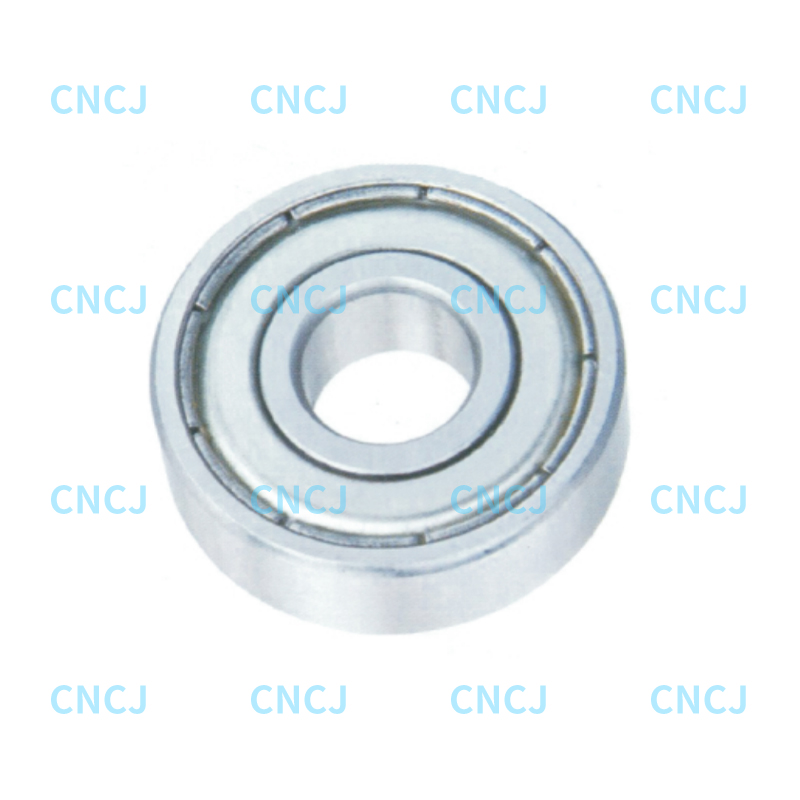

In the field of precision machinery, the performance of each component is related to the stability and precision of the entire system. Among them, Double Row Angular Contact Ball Bearings, as a key transmission component, plays an important role in long-term, high-load working environments with its unique design and good performance.

The design feature of Double Row Angular Contact Ball Bearings is that it can simultaneously withstand radial loads and axial loads in two directions, as well as moment loads. This multi-directional load-bearing capacity makes it an ideal choice in precision machinery, especially in situations where axial displacement needs to be precisely controlled and complex loads need to be borne. High rigidity is another major advantage of double-row angular contact ball bearings, which can ensure that the mechanical system maintains a stable operating state at high speeds, reduce vibration and noise, and improve overall performance.

For any bearing, lubrication is the key to maintaining its performance. Double Row Angular Contact Ball Bearings are no exception. In precision machinery, regular inspection and replacement of lubricating grease is a necessary measure to ensure that the bearing interior remains sufficiently lubricated and reduce friction and wear. In addition, keeping the bearing and its surroundings clean is also an important step to extend the life of the bearing. Regular cleaning can remove dust and impurities, preventing them from entering the bearing and causing damage.

Precision machinery has strict requirements on the working environment, including factors such as temperature, humidity and vibration. Double Row Angular Contact Ball Bearings need to be in suitable working conditions to perform their performance. Excessive temperature or humidity may cause the performance of the bearing material to deteriorate, while vibration may accelerate the wear of the bearing. Therefore, when using Double Row Angular Contact Ball Bearings, it is necessary to ensure that the working environment of the mechanical system meets the relevant requirements and take corresponding measures to reduce vibration and shock.

The material and manufacturing quality of the bearing directly affect its service life and performance stability. Double Row Angular Contact Ball Bearings are usually made of high-quality steel or special alloy materials, which have excellent wear resistance, fatigue resistance and corrosion resistance. At the same time, advanced manufacturing technology and strict quality control process are also important guarantees to ensure the performance of the bearing. Through precise turning, grinding and heat treatment processes, the dimensional accuracy, surface quality and rationality of the internal structure of the bearing can be ensured, thereby improving its overall performance.

English

English 中文简体

中文简体 Deutsch

Deutsch Español

Español